Structural Steel Blasting by Stripmasters

We are one of the elite structural steel blasting and painting facilities in the St.Louis/Metro East area. Stripmasters has a rich history in structural steel painting since 1986 and endless possibilities to handle all types of blasting needs.

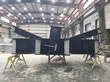

Our main facility has two, 5 ton overhead cranes and 22,000 square feet. This facility is completely climate controlled to sustain a constant temperature to insure a quality finish. We also have a Pangborn blast machine which we can run various parts through. The blast cabinet is 4 feet by 10 feet tall with a crane slot to run plates. Our newest edition to the Stripmasters family is an 8,000 square foot expansion. This new expansion has a 5 ton overhead crane and another automated blast system for smaller parts. Our outside capabilities feature a sandblasting operation to handle any size part and (3) 17,000 lb. forklifts to service the shops with steel.

We also have a covered outside blast pit that allows us to do much larger parts that do not fit through our automated line. Weather is not an issue since the pit is covered and protected from the elements.

Liquid Paint Applications

Along with our blasting capabilities we also offer industrial and commercial liquid paint applications. All of our painting operations are done indoors out of the environmental elements. Stripmasters is proud to be AISC certified with an enclosed endorsement for sophisticated painting. Our quality control is a non stop major part of our daily process. We track all essential elements that are a factor in liquid painting such as humidity, air temperature and steel temperature. All of these factors are tracked on a daily basis to insure that the conditions are right for painting your product. Everyday our QC department checks all steel that has been blasted against the SSPC code for correct cleanliness, correct mil profile and any contaminants that could cause a coating problem. Once the QC department has determined that the prep work has been done per code stipulations, we then apply the coating. All of our painters here at Stripmasters are certified for coating applications. All coatings are carefully inspected in process for paint thickness using a wet mil gauge. Once the coating has dried, QC once again checks the paint thickness per code and/or customer specs. After approval from QC, the parts are then loaded out for shipment. All painted steel is handled with nylon straps as to avoid any damage during loading. The steel is then inspected a third time for any areas that may need touch up prior to the customers end product leaving our facility.